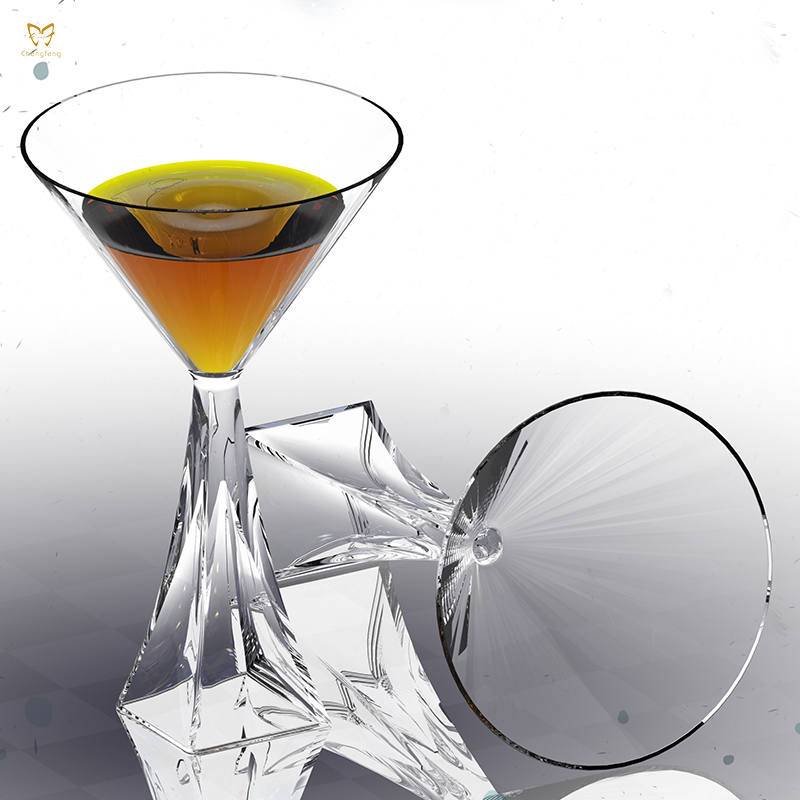

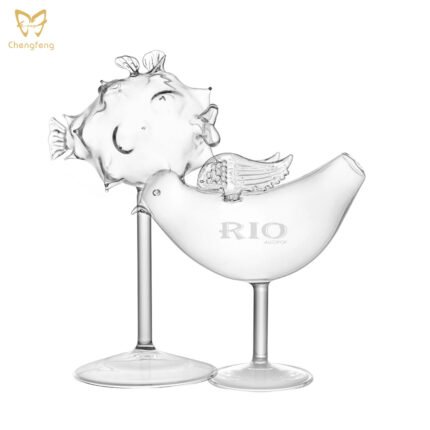

CG1210 Tower Shaped Cocktail Glass 360ml

| Model | CG1210 Cocktail Glasses |

| Product Name | 360ml Cocktail Glass |

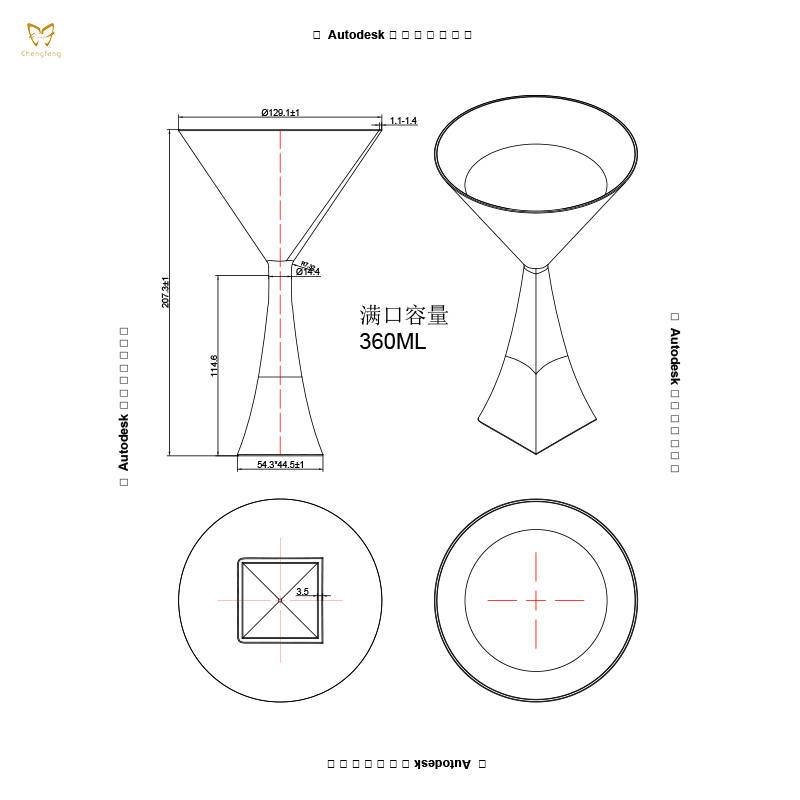

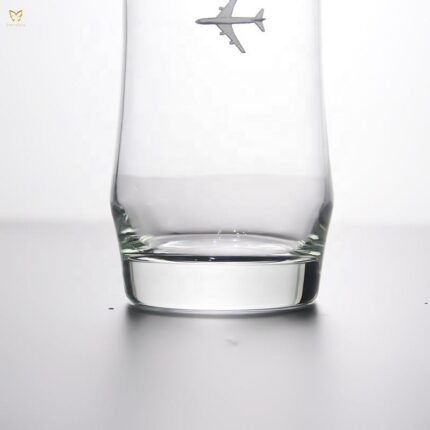

| Product Dimension | H:207mm/TD:129mm/BD:54mm/C:360ml |

| MOQ | 1000 |

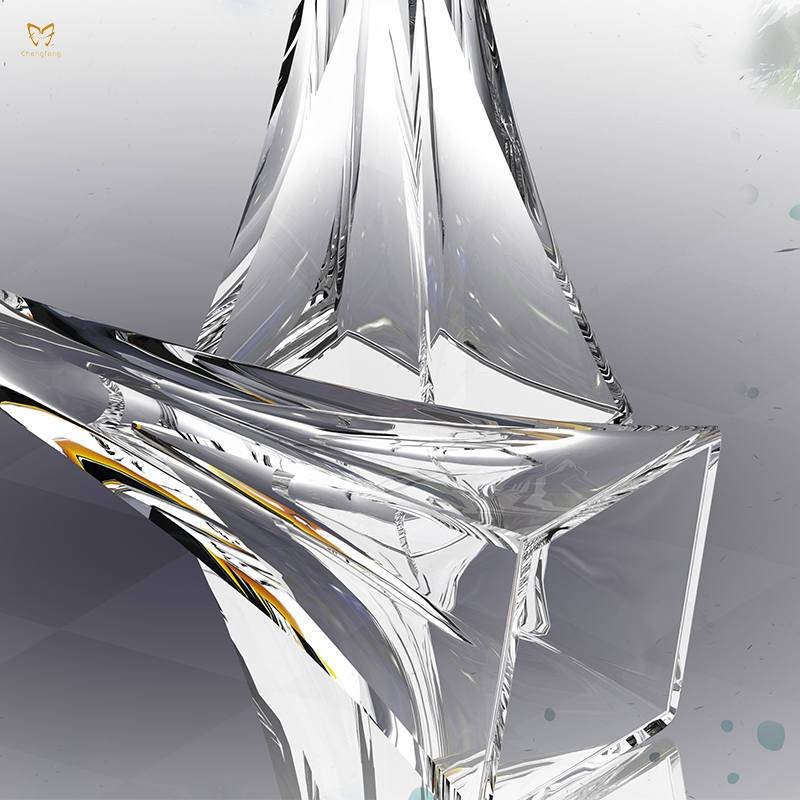

| Material | Lead Free Crystal Glass/Soda-lime Glass |

| Packing | Inner box and 5-layer export carton |

| Certification | FDA&EU Leachable Lead and Cadmium Safety Report |

| Quality control | ISO9001, ISO14001,Totally OEM Quality |

| Deep processing | Decaling,silk screen printing,etching,sandblasting,engraving, color coating, glass frosting, pate-surpate, outline in gold and glaze spraying. |

| Delievery term | FOB/ C&F/CIF |

| Payment terms | T/T, L/C |

| Lead time | 15 to 20 days after ordered for normal type.For new design drawing confirm within 3 days, mold within 15 days, produce in bulk within 30 days. |

Advantage ? 100% lead-free crystal provides highest degree of clarity and brilliance ? Hand made&Professional grade ? Lead-free. Dishwasher Safe for easy care and clean up. ? Modern, yet casually elegant, these glasses are perfect for any occasion ? All-purpose glass works equally well with cocktails or any mixed beverage ? The design of the cup pole is the shape of the tower, and the unique and innovative shape is impressive. ? MOQ for bulk production is 5000 pcs About Manual Blown Glass Manual blowing is divided into rotary blowing method and static blowing method. The rotary blowing method uses a round mold with a smooth surface, which is used to produce round water cups, vases and other products. The product has a smooth surface, and the seam line of the mold is not visible, and the appearance is more beautiful; the static blowing method mainly uses non-circular molds or Molds with patterns on the surface produce square cylinders, curved glass products, etc. There are obvious mold joints on the surface of the product, and the appearance is not as smooth as the blow-through method. How to make glass smoother in production? The mold used in the transfer blowing method needs to be on the inner surface of the metal mold, using a dry oil such as linseed oil or tung oil as a binder, and evenly spread soot, cork powder or fine coke powder on the inner surface of the mold, and heat it to 240?? Left and right to make it firmly bond with the inner surface of the mold. Before the mold is used, pick a group of hot glass and place it in the mold. The hot glass is in full contact with the mold soot to make the surface of the mold smooth. It needs to be cooled with water during use, and the material bubble forms an air cushion layer with the mold surface to facilitate the rotation of the material bubble, so that the surface of the product produced is smoother and the size is more accurate.